Technology

Built To Revolutionize Green Lithium Extraction

At Ensorcia, we strive to offer timely sustainable and low carbon solutions to the battery industry.

The Ensorcia Group employs the IBAT DLE technology, a cost-effective and resource-efficient process, offering an environmentally friendly alternative to traditional lithium extraction methods. This technology has been developed by Dr John Burba, a pioneer in Lithium extraction with more than 40 years of experience in critical metals and lithium extraction.

“We believe that our technological advantages will allow [us] and our partners to lead the world in green lithium production.” – Dr. John Burba

This approach also provides a timely solution to meet the surging demand associated with the expansion of the EV and battery storage market (more detailed information on Advantages of Ensorcia’s processing.

Our Technology & Social Impact

With this proprietary and revolutionary technology, Ensorcia can produce high-quality lithium at a much lower cost than the current industry standard.

We strive to enable the battery industry to realize the full potential of renewable energy.

Environmental Advantages

Time to Market

Capital & Operating Costs

Advanced Technology

Lithium Brine Extraction

Our unique technology can quickly get us to the production stage, which is essential to our strategy to set us apart from all other lithium companies.

An essential part of Ensorcia’s strategy is to differentiate itself from the pack of lithium-oriented venture-stage pilot plant companies, by quickly going to the production stage.

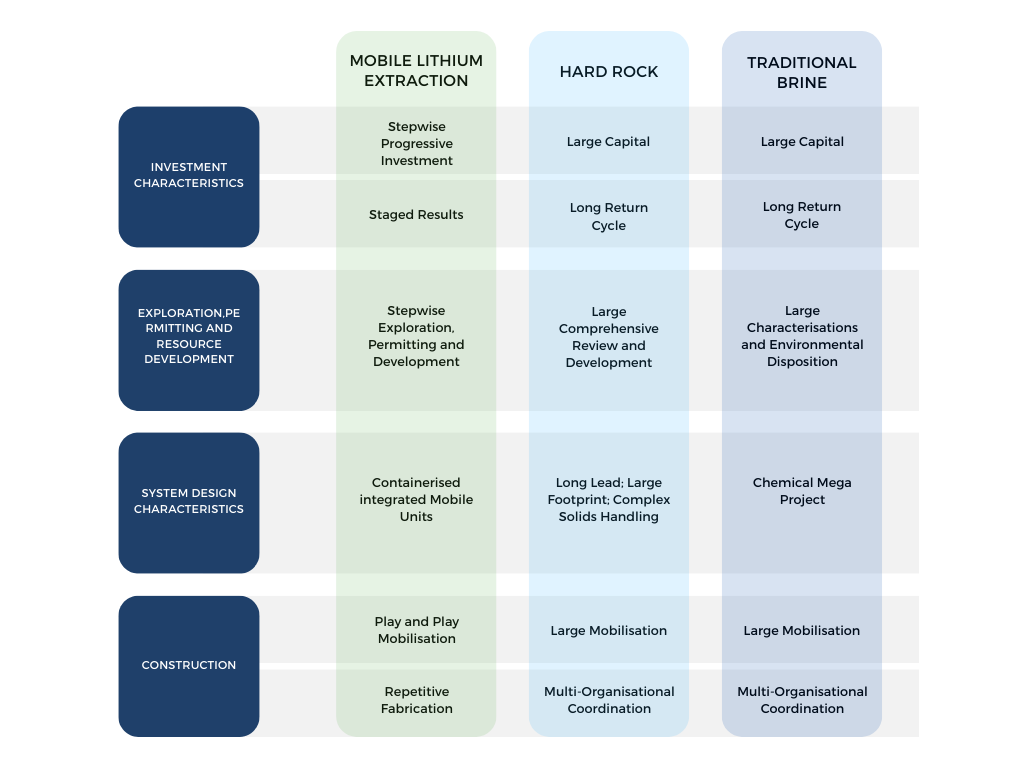

Mobile Lithium Extraction Process

The IBAT mobile technology has great advantages to secure and accelerate its deployment:

- Prebuild and fab-tested before deployment

- Can be easily deployed in isolated locations, with often difficult access such as in high altitude environment

- Can be deployed with a progressive expansion program over time allowing for quick start-up before entire resource is developed

The independent modular design offers redundancy, which minimizes downtime, allowing for continuous production during maintenance.

The high characteristics of the IBAT DLE technology is brine agnostic, allowing it to operate either on low or high Lithium concentration and wild range of impurities, while often DLE technologies are thought for a given type of brine.

Also, its modular concept makes it easy to adjust the configuration to best fit the characteristics of the brine, such as brine pre-cleaning for oilfield brines.

The IBAT proprietary process has been proven at commercial scale (mobile unit of up to five thousands TPA LCE, depending on brine concentrations), giving both the proof at scale of its efficiency and the real vision of its cost, and confirmation of its ability to provide one of the highest battery grade Lithium at optimized cost, in a much shorter timeframe.

The IBAT Technology licensed to the Ensorcia Group is the only modular DLE third party proven at commercial scale, as of 2023.

The certification has been processed in August 2022 by the third party independent expert SLR Consultants on the first standard mobile unit at size (5.6 kTPA LCA / 1800 ppm) built with the financial support of the Ensorcia Group (click to download the IBAT Modular Direct Lithium Extraction Plant Performance Review Summary).

In the meanwhile, IBAT enhanced even more the technology, having new third-party verification confirming a 95% Lithium extraction rate (versus 42 to 55% with traditional process), and over 98% of potential clean brine reinjectable.

The Modular DLE plant was deployed on a production site in Utah early 2024, with an ultra fast and efficient project delivery. Once this project was approved, it took no more than 3 month to pack, ship accross the US East to West, unpack, setup the plant and commission it. It proved during the next 5 month outstanding results, despite of highly contaminated lithium brine resources, with a production capacity proven of 4.000 TPA LCE (reported to effective operating hours linked to site constraints), and ultra-pure LiCl that was converted to 99.9% battery lithium grade carbonate. Refer to IBAT web site for a more detailled white paper on this effective probation at commercial size.

Ensorcia is the clean, socially conscientious alternative that’s driving the green energy revolution.

SOURCES FOR LITHIUM EXTRACTION

Ideal Lithium Baring Brines

Along With Evaluating And Potentially Licensing Lithium Extraction Process, Sorcia Minerals Has Also Begun Its Efforts To Secure Access To Lithium Baring Brines That Are Ideal For Lithium Extraction From Brine.

Key Selection Criteria

- Documentation of high lithium and TDS content of brine

- Volume of brine potentially available and materiality of potential developed asset

- Availability of existing brine production infrastructure

- Ownership and whether present owner is motivated to sell or lease access

- Geologic certainty of resources, focus on low/no risk

- Factors affecting title and certainty of ownership

- Expansion possibilities

- Operating costs

- Labor market considerations

- Surface access considerations

- Regulatory environment considerations

- Energy availability (for process heat)

- Takeaway transportation nearby including rail lines and roadways

IBAT Modular Direct Lithium Extraction Plant Performance Review Summary

Read the full Report